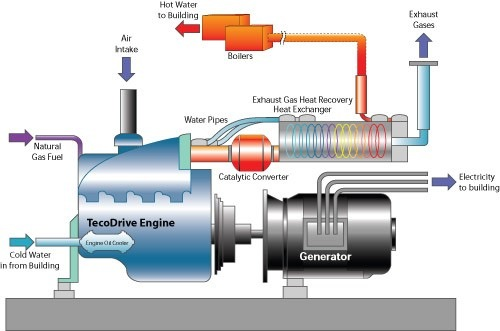

How It Works

Our system uses a natural gas-fueled engine to generate electricity and hot water twice as efficiently as the grid.

Electricity is fed into the building, thereby reducing the facility’s electrical consumption and utility bill significantly. At the same time, free “waste” heat is recovered and used to offset fuel that would otherwise have to be burned in the site’s water heaters and boilers. This allows the site’s boilers to not have to work as hard so the site’s gas bill (e.g., for space heating, domestic hot water (DHW), process hot water, pool heating, etc.) is also reduced.

Benefits

Tecogen's Cogeneration products offer significant benefits including

50%

Reduction in utility-related operating costs

50%

Reduction in greenhouse gas (GHG) emissions normally associated with electricity and hot water production

Save on electricity, demand charge reduction

Ultra-low emissions with near zero criteria pollutants

Compact size, fits through a standard doorway

Immense carbon savings, reduce your facility’s environmental impact

Real time monitoring